Features

- 12 solid-state high-side outputs (no fuses or relays)

- Up to 150A total continuous current

- Per-channel current monitoring and protection

- CAN bus control and telemetry output

- iOS / Android app + web interface

- Supports CAN keypads with RGB button feedback

- Configurable safety features and fault detection

- Designed for motorsport and professional installations

- Scripting for custom program-your-own modules

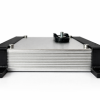

Product Description

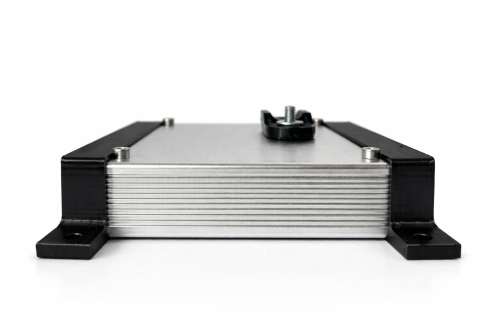

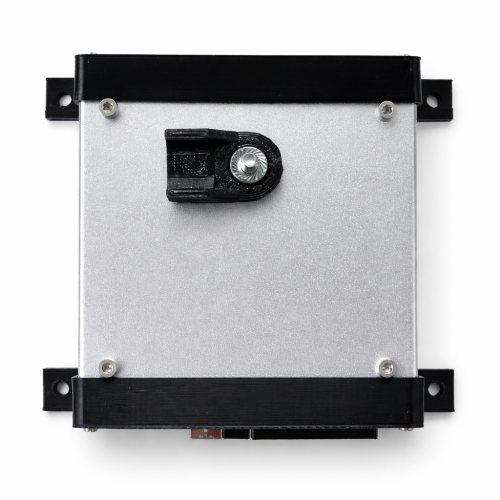

The LDperformance PDM / PMU (Power Distribution & Power Management Unit) is a fully solid-state, CAN-enabled power management system designed to replace traditional fuse boxes and relay panels in performance, motorsport, and custom vehicle builds.

With 12 independently controlled outputs, real-time current monitoring, and comprehensive electronic protection, the LDperformance PDM/PMU provides a modern, reliable solution for managing all vehicle electrical loads — from fuel pumps and cooling fans to ignition systems, lighting, and auxiliary devices.

The unit integrates seamlessly with MaxxECU, ECUmaster, Haltech, Link ECU, and any ECU with CAN bus support, thanks to fully customisable CAN settings. CAN parameters such as RPM, coolant temperature, speed, or gear can be used directly to control outputs, enabling advanced ECU-driven power strategies without additional hardware.

Configuration and monitoring are handled via the LDperformance PDM app (iOS & Android) or the built-in web interface, providing live telemetry, fault diagnostics, and easy configuration backup. Contact us to get access to beta app.

Pinout

Power Distribution & Power Management (PDM / PMU)

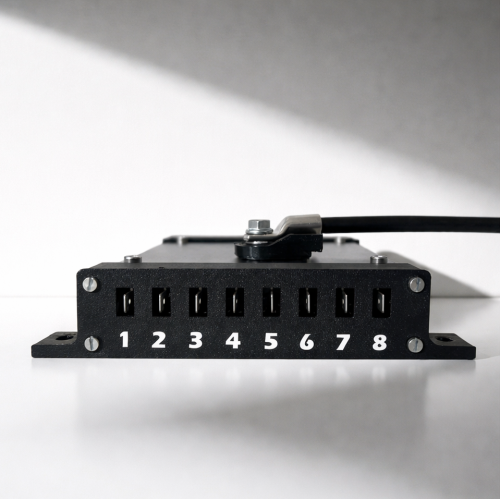

- 12 solid-state high-side outputs

- Outputs 1–8: up to 30A continuous, with integrated temperature monitoring

- Outputs 9–12: up to 10A continuous

- 150A total continuous system capacity

- Replaces fuses, relays, and traditional PMU systems

- Per-channel current measurement with 1A resolution

ECU & CAN Bus Integration

The LDperformance PDM / PMU is designed to work with modern engine management systems:

- Compatible with: MaxxECU, ECUmaster, Haltech, Link ECU, Any CAN-enabled ECU

- Fully configurable CAN IDs, scaling, and data types

- CAN-based triggers for:

- Fuel pumps

- Cooling fans

- Ignition and engine power

- Safety shutdowns

- CAN telemetry output for data logging systems

Thanks to customisable CAN configuration, the PDM/PMU can be adapted to virtually any ECU or CAN-based vehicle network.

Protection & Reliability

- Configurable over-current protection per channel

- Hardware and software short-circuit protection

- Over-temperature shutdown (outputs 1–8)

- Under-voltage and ground fault detection

- Fault latching with clear visual feedback

- Designed for harsh automotive and motorsport environments

Control & Integration Options

- CAN bus control

- Compatible with most CAN-enabled ECUs

- Supports RPM, coolant temperature, speed, gear, and more

- CAN keypads

- For driver control, the PDM / PMU supports up to 4 CAN keypads with tactile buttons and RGB status LEDs. The LDperformance CAN Keypad provides intuitive control of ignition, fuel pumps, fans, lighting and auxiliary systems, with real-time fault and status feedback directly on the buttons.

- Analog inputs: 10 configurable inputs for switches and sensors

- Mobile app: Full configuration, monitoring, and diagnostics

- Web interface: Browser-based configuration from laptop or tablet

Monitoring & Telemetry

- Real-time current monitoring on all 12 outputs

- Integrated temperature sensors (outputs 1–8)

- Live system voltage monitoring

- CAN telemetry output for data logging systems

- Configuration export/import for backup and cloning

The LDperformance PDM / PMU outputs live CAN telemetry including per-channel current, temperature and system voltage, making it ideal for integration with a motorsport data logger. When paired with the LDperformance Data Logger, power usage and electrical data can be recorded alongside ECU data for full post-session analysis.

Built-In Special Functions

- Fuel pump prime

- Soft-start for motors and fans

- Cooling fan control via CAN temperature

- Turn signals / hazard flashing

- Wiper control with park function

- Sleep mode with ultra-low standby current

- External master on/off input

- Dual-PDM support for larger systems

Typical Applications

- Motorsport and race cars

- Track day and time attack cars

- Rally and endurance vehicles

- Restomods and high-end builds

- ECU-controlled engine management systems

- Vehicles requiring advanced electrical diagnostics

System Requirements

- Supply voltage: 6–16V DC (12V systems)

- Configuration device:

- iOS or Android (Bluetooth), or

- Laptop/tablet (WiFi)

- Optional: CAN-enabled ECU

- Keypads: LDperformance CAN keypads (up to 4)

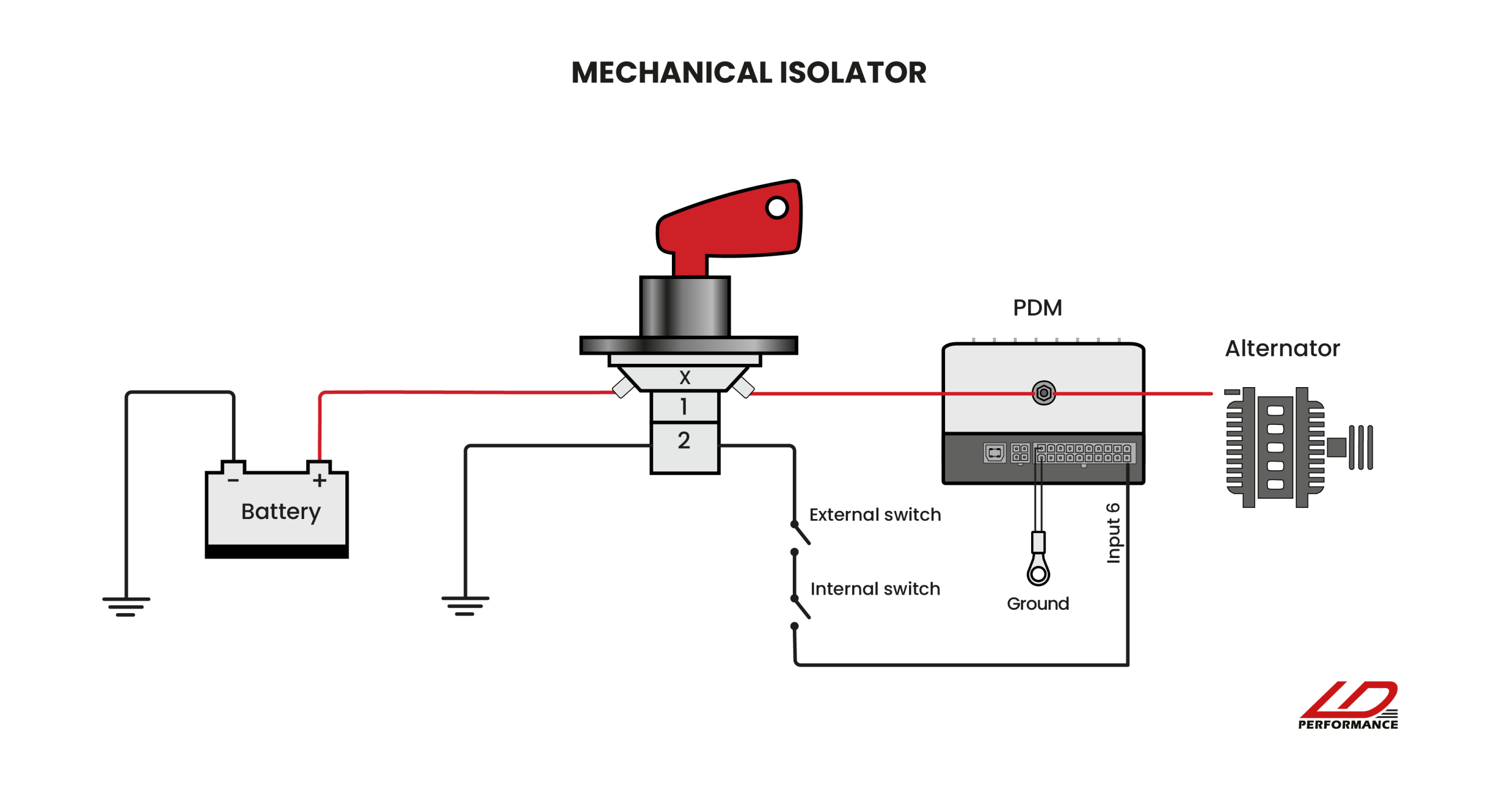

Battery disconnect switch & FIA rules

The unit is compatible with any battery cut-off switch – mechanical, relay or solid state. It also allows all outputs turn on/off by external switch.

FIA rules:

CIRCUIT BREAKER 141-2 Mandatory on all Vehicles. The general circuit breaker must cut all electrical circuits (battery, alternator or dynamo, lights, ignition, electrical controls, etc.) and must also stop the engine. It must be a spark-proof model and must be accessible from inside (in Drivers reach) and outside the Vehicle.

This can be easily achieved using a mechanical battery cut off or relay as shown in the diagram:

Note: It is a requirement that it also stops the engine – the ground signal connected to input 6 of the PDM is used to turn off all outputs, effectively turning off the engine at the same time as the battery disconnect. Without this, the engine will keep running, getting power from the alternator even with the battery disconnected.

![]() PDM User Manual (PDF) Download

PDM User Manual (PDF) Download

Reviews

There are no reviews yet.